Mars Climate Orbiter

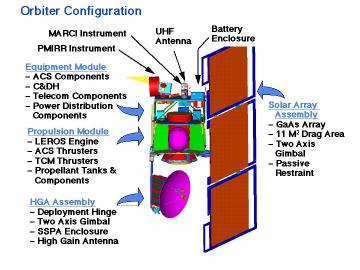

Flight System Description

|

3-Axis Stabilized

|

|

Four 5-lbf Trajectory Correction Manuever Thrusters, used also for Pitch & Yaw

|

|

Four 0.2-lbf thrusters for Roll control

|

|

Reaction Wheels

|

|

Star camera + IMU, analog sun sensors backup

|

The Orbiter is 3-axis stabilized in all mission phases following

separation from the launch vehicle. The primary attitude determination

is via star camera derived from the Clementine spacecraft star camera hand an inertial measurement unit, and is backed

up by analog sun sensors. Reaction wheels provide primary attitude

control during most mission phases, and are desaturated via RCS

thrusters. Because of IMU lifetime concerns, the IMUs will be

turned off during significant portions of Cruise and Mapping,

and the vehicle operated in all-stellar mode. except during maneuvers.

The RCS thrusters also provide attitude control during trajectory correction

maneuvers (TCM's),

Mars Orbit Insersion (MOI), aerobraking drag pass, Orbital Trim Maneuvers (OTM's), and safe mode

In all, four

5-lbf thrusters are used for TCM's and pitch/yaw control. Four

0.2-lbf thrusters are used for roll control.

|

RAD6000 Processor

|

|

128 MBytes Data Storage

|

The RAD6000 32 bit processor developed for

the Mars Pathfinder Project and embedded in the orbiter Command and Data

Handling (C&DH) subsystem provides a central processing capability for

all spacecraft subsystems including the payload elements. Electronic cards

are provided to interface instruments and subsystems to the command and

data handling (C&DH) subsystem. 128 Mbyte of data storage is provided

on the processor card, although the spacecraft uses approximately 20% of

this for its own internal programs. The rest of the space in the memory

is used for science programs and data storage for sending back to Earth

either from the lander and/or the orbiter.

|

Cassini Deep Space Transponders

|

|

15 Watt Radio Frequency Solid State Amplifiers

|

One 1.3 meter High Gain Antenna (Transmit/Receive)

|

One Medium Gain Antenna (Transmit Only)

|

|

One Low Gain Antenna (Receive Only)

|

|

UHF 10 Watt Radio Frequeny System for 2-way communications with Lander

|

Primary communication between the Earth and the

orbiter is by use of the Deep Space Network (DSN) X-band (up/down) link

and the orbiter’s deep space transponder developed for the Cassini

spacecraft, a 15 Watt RF solid state amplifier, and a 1.3 meter (4.3 ft)

diameter articulated (2-axis) high gain antenna. A two-way UHF link (i.e.,

commands from Earth passed through to the lander and receipt of data from

the lander) is provided for on-orbit communication with the lander while

it is on Mars.

|

Single, 3 Panel GaAs/Ge Solar Array, 2 axis gimballed

|

|

NiH2 CPV Batteries

|

A 2 axis articulated, gallium arsenide solar array (7.4m^2 (80

ft^2) cell area) provides power and serves as the most significant drag brake

during aerobraking passes (11m^2 (118 ft^2) total wing area). Nickel-hydrogen

(NiH2) 16 amp-hour, common pressure vessel batteries provide power during

eclipses and for peak power operations. The electrical power control electronics

are derived primarily from the Small Spacecraft Technology Initiative (SSTI)

spacecraft development.

|

Passive: Louvers, MLI, Kapton, Paints, Dedicated Radiators

|

|

Thermostatically Controlled and Computer Controlled Heater Circuits

|

The thermal control subsystem uses passive methods and

louvers to control the temperature of the batteries and the solid state

power amplifiers. Passive coatings as well as multi-layer insulation blankets

are used to control the temperatures. Where needed, radiators are used

to take the excess heat out of the spacecraft components to keep them at

their proper operating temperature.

|

Biprop System For Mars Orbit Insertion Only

|

|

Hydrazine TCM Thrusters (4 5-lbf Thrusters)

|

The propulsion subsystem is similar to the Mars Global

Surveyor (MGS) spacecraft. The LEROS 640 N (144 lbf) main engine uses

bipropellant mode (i.e., hydrazine fuel and nitrogen tetroxide oxidizer)

for MOI, when a large thrust is required to slow the spacecraft down. Following

MOI, the oxidizer is gone and the RCS 22.4N (5 lbf) and 0.9N (0.2 lbf) thrusters

use the remaining monopropellant (i.e., hydrazine fuel) for all other propulsive

maneuvers. This type of propellant system is termed "dual mode,"

since it works with bipropellant and monopropellant.

|

Composite Facesheets on Aluminum Honeycomb

|

The orbiter structure is comprised of two modules: a gusset

plate construction propulsion module scaled down from the Mars Global Surveyor design, and

a truss construction equipment module. Both modules use aluminum honeycomb

with composite face sheets.

|

Sofware Fault Protection

|

|

Critial Items Cross-Strapped

|

Most orbiter subsystem components are redundant with critical

items cross-strapped. A software fault protection system is used to protect

the spacecraft from reasonable, credible faults but also has resiliency

built into it so many faults not thought of can be accommodated without taking

the spacecraft down.